Plumbing & Casing Pipes - ASTM-D1785

Blue & White pipes made under this American Standard, along with matching fittings such as sockets, reducing sockets, elbows, etc., are used specifically in plumbing, as bore-well casings, for water & liquid chemical supplies, and for hanging tube-well cylinders from hand pumps. Pipes manufactured to match this specification are threaded on both ends to join pipes with matching fittings, forming a pipeline system for supplying the required fluid to the discharge point. These pipes are made in three pressure ratings: Schedule-40 (Light Duty), Schedule-80 (Medium Duty), and Schedule-120 (Heavy Duty). Dimensional specifications along with internal water pressure ratings for each size are as follows.

uPVC Pipes made as per ASTM-D1785

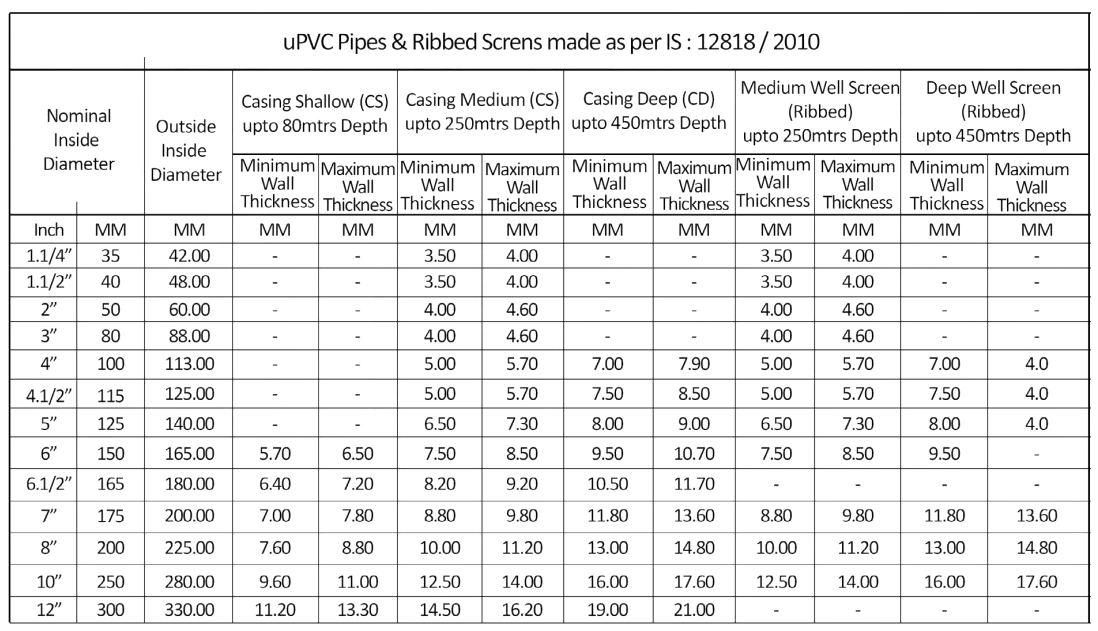

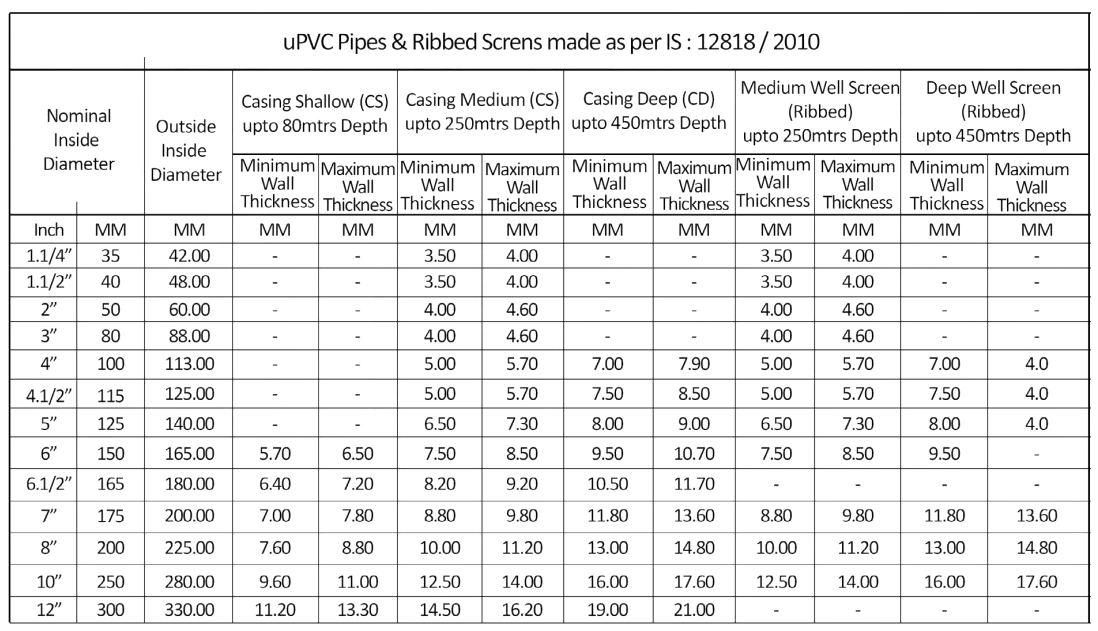

Casing & Screen Pipes-IS: 12818/2010

Blue & White pipes made under this American Standard, along with matching fittings such as sockets, reducing sockets, elbows, etc., are used specifically in plumbing, as bore-well casings, for water & liquid chemical supplies, and for hanging tube-well cylinders from hand pumps. Pipes manufactured to match this specification are threaded on both ends to join pipes with matching fittings, forming a pipeline system for supplying the required fluid to the discharge point. These pipes are made in three pressure ratings: Schedule-40 (Light Duty), Schedule-80 (Medium Duty), and Schedule-120 (Heavy Duty). Dimensional specifications along with internal water pressure ratings for each size are as follows.

uPVC Pipes & Ribbed Screns made as per IS: 12818/2010

Potable Pipes & Fittings - IS: 4985/2000 & IS: 10124/2009 (Part 1 to 10)

Grey and fittings manufactured as per these Indian Standards are widely used for supplying potable water and other liquids. In some cases, they are also applied as bore-well casings and screens. Extensively laid in fields for irrigation, these pipes support long-distance water supply. Fittings such as couplers, bends, tees, reducers, and flanges ensure proper connections. Designed to withstand hydrostatic pressure up to 12.5 kgf/cm², they come in six pressure ratings from 2.5 to 12.5 kgf/cm².

uPVC Pipes made as per - IS: 4985/2000

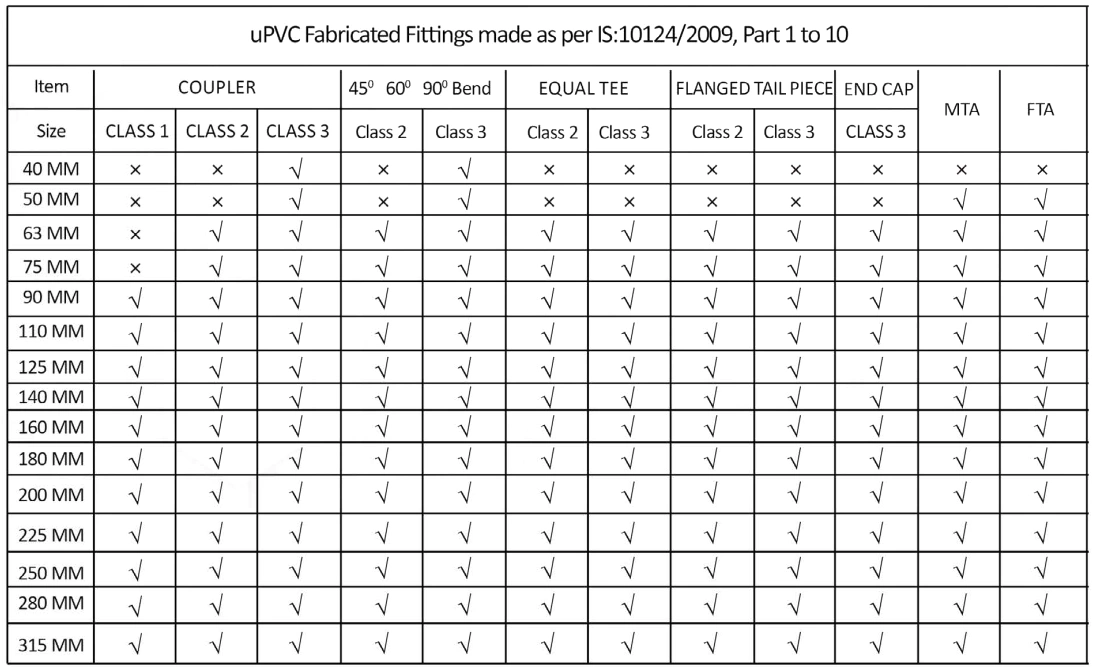

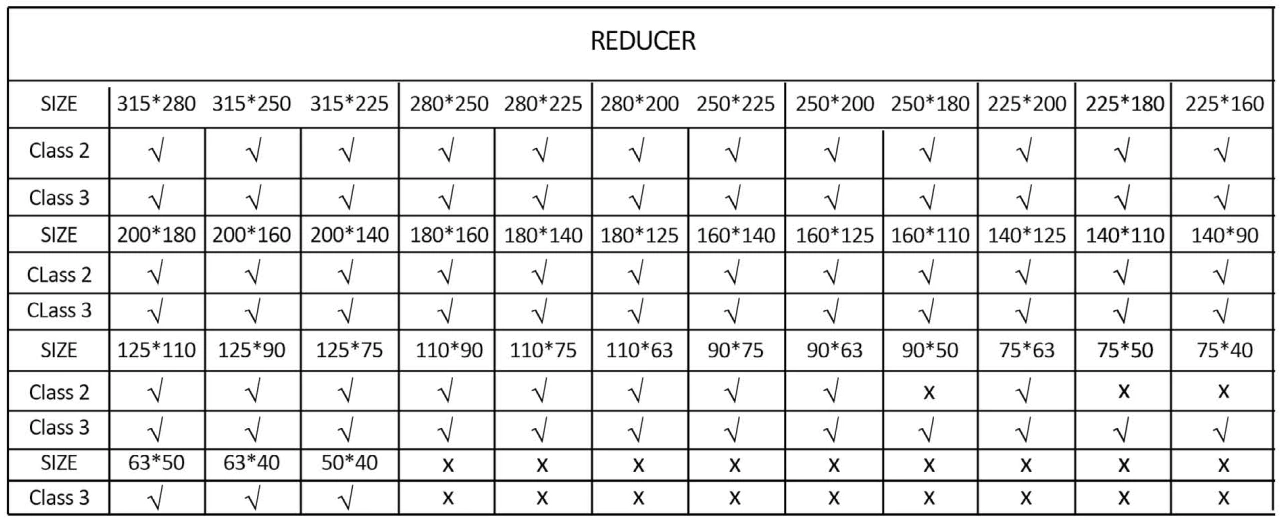

uPVC Fabricated Fittings Made As Per IS: 10124/2009, Part 1 To 10

uPVC Fabricated Fittings made as per IS: 10124/2009 (Part 1 to 10) are designed to provide strong, leak-proof connections for pipelines used in water supply, irrigation, and industrial applications. These fittings are manufactured with high-grade unplasticized PVC material, ensuring durability, chemical resistance, and long service life. They are lightweight, easy to install, and suitable for both above-ground and underground piping systems. Available in a wide range of types such as elbows, tees, reducers, couplers, end caps, and flanges, these fittings maintain dimensional accuracy and withstand internal pressure, making them a reliable choice for modern piping networks.

uPVC Fabricated Fittings Made As Per IS: 10124/2009, Part 1 To 10

SWR Pipes & Fittings - IS: 13592/2013 & IS: 14735

Grey Pipes made under this Indian Standard are used for discharging soil waste and rain water from buildings. These pipes, along with molded fittings specially made to fit them, form a critical part of modern building sanitary systems. The "O" Ring type sockets on pipe ends allow self-fitting with sealing rings, creating a complete sanitary discharge system. Lightweight design ensures easy installation. Dimensional specifications and specific applications are maintained as per standards.

SWR Pipes & Fittings - Technical Specifications

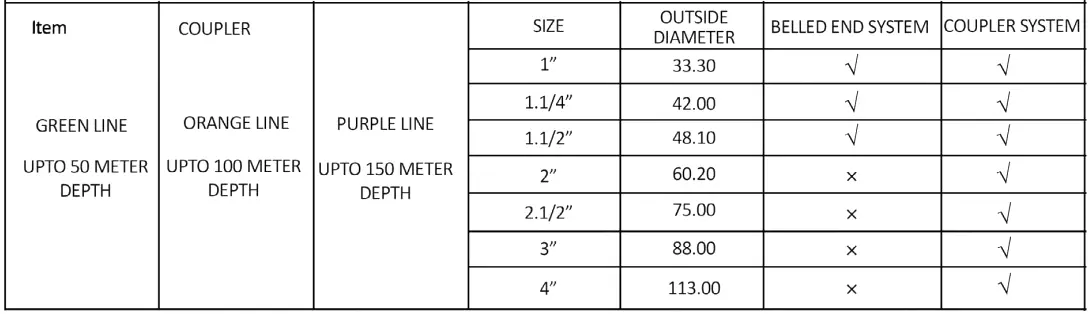

Column Pipes

Column Pipes are a recent development. These pipes are used as riser mains from bore-well. Column Pipes have very high tensile strength to hold the submersible pupms joined with them in the bore-well. Column pipes have come as a boon for domestic small diameter bore-wells as they reduce the total cost of a bore-well drastically. Column pipes are made in small diameter starting from 1" to big diameter of 4". Super Heavy Duty Column Pipes can hold submersible pumps upto a depth of 1000 feet. Dimensional specifications along-with specific length of each size column pipe size are as followed :-

uPVC Submersible Pump And Cylinder Hanging Column Pipe

Solvent Cement-IS: 14182/1994

uPVC Pipes are joined by applying a thin layer of sovent cement on both male and female side after cleaning and roughening the surface by scrubbing with sand paper. Sovent Cement first softens the surface and then solidifies into tough bond.

PVC Solvent Cement Made As Per IS: 14182/1994

HDPE Pipes

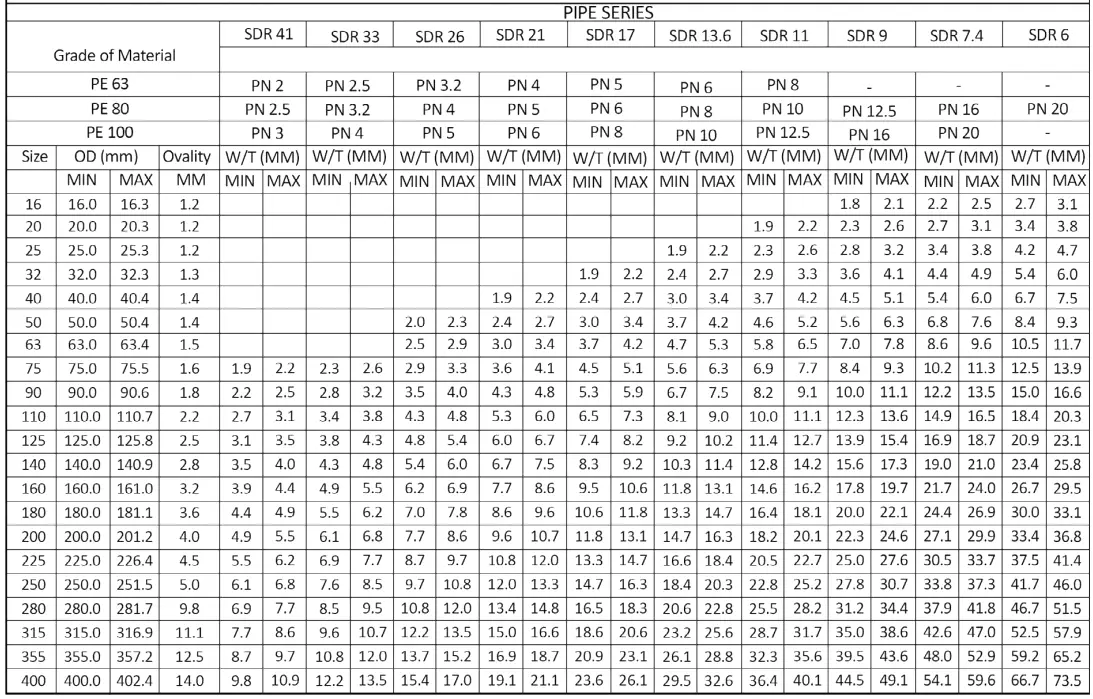

GK Plastics Pvt Ltd manufactures a wide range of Polyethylene pipes, High Density (HDPE) conforming to various standards viz., BIS, BS, DIN & ISO to name a few. (HDPE) is strongly resistant to stress cracking and has low creep-rupture properties. It comes with excellent insulation properties over a wide range of frequencies and is not chemically active. These pipes are one of the two largest thermoplastic pipelines available and by far the most versatile. These pipes have a wide variety of applications ranging from drinking water supply systems, Electrical Conduit System, Sewerage pipe systems, Ducting system, Oil and Gas supply systems. Polyethylene is a thermoplastic polymer consisting of long chains of ethylene or ethane. It is a wax-like thermoplastic with a density less than that of water. The only two additives added to polyethylene are Carbon Black, within the range limit of 2-3%, to add reinforcement and increase polyethylene's weathering properties, and trace amounts of antioxidants. The pipes and fittings are offered in PE 63, PE 80, and PE 100 grades, in compliance with IS 4984. Dimensional specifications along with pressure ratings for each size are as follows:-

Dimensions Of HDPE Pipes As Per IS: 4984 / 2016

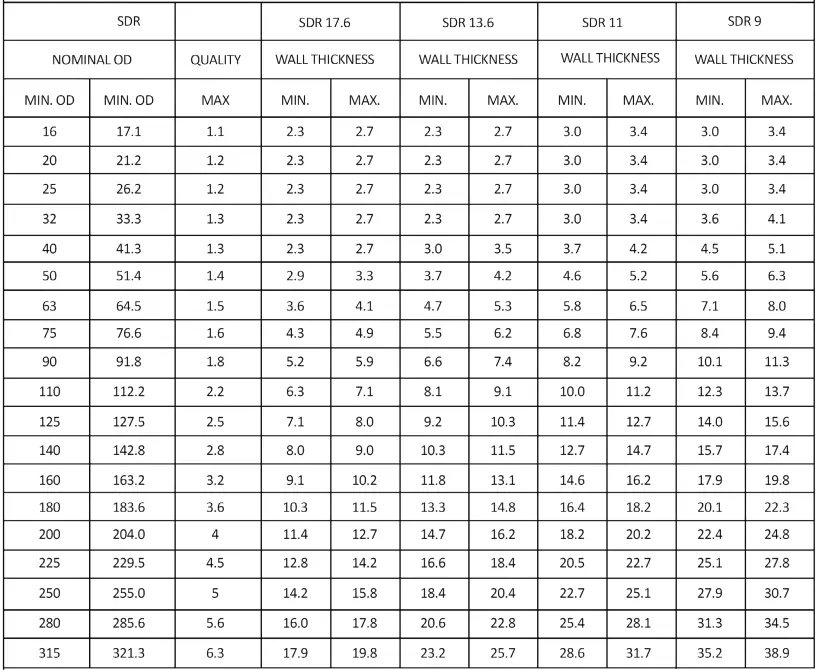

MDPE Pipe

MDPE (Medium-Density Polyethylene) pipe is a reliable and durable solution, widely recognized for its exceptional performance in gas distribution systems. Its proven track record of longevity and operational efficiency makes it a preferred choice in various utility applications. These pipes are typically color-coded for specific uses—blue for water, orange for gas, and yellow for petrol—ensuring easy identification and safety compliance.

MDPE gas pipes are extensively used in gas distribution networks due to their inherent advantages, including:

- Corrosion resistance

- High flexibility

- Excellent crack resistance

- Superior toughness

These properties make MDPE an ideal material for ensuring a safe, long-lasting, and low-maintenance gas piping infrastructure.

Dimensions Of MDPE Pipe As Per IS 14885

Suction Hose Pipes

Designed for efficient suction and discharge of liquids in agriculture, industry, and domestic applications. High-quality, flexible material ensures vacuum pressure resistance and durability.

Suction Hose Pipes - Technical Specifications

Garden Hose Pipes

Perfect for watering gardens, lawns, and plants. Durable, UV-resistant, flexible, and kink-free. Compatible with standard fittings for efficient water delivery.

Garden Hose Pipes - Technical Specifications

Braided Hose Pipes

Reinforced with braided layers for extra strength and high-pressure resistance. Ideal for water, air, and chemical transfer in industrial and domestic applications. Flexible, kink-free, and durable.

Braided Hose Pipes - Technical Specifications

Industries Using Our Pipes

Our pipes are engineered for strength, versatility, and endurance — serving diverse applications across industries worldwide.

Water Treatment

Oil & Gas

Agriculture

Food Processing

Beverage Industry

Chemical Plants

Power Plants

Telecom

Pharmaceuticals

Mining

Paper & Pulp

Textile Industry

Construction

Real Estate

Airports

Railways

Automotive

Refineries

Marine Sector

Industrial Cooling

Fire Safety

Drainage

Institutions

Hospitals

Cold Storage

Data Centers

Dairy Farms

Municipal Uses

Steel Industry

Plastic Industry

Contact Info

Phone Number

Email Address

Location

G K Plastics Pvt. Ltd. Rajhat, SH-13, Delhi Road, Hooghly, West Bengal - 712123, India